A new path for soft plastic packaging in Australia

The National Plastics Recycling Scheme (NPRS) project is being developed by Australia’s food and grocery manufacturing industry with funding support from the federal government. The NPRS project is designing Australia’s largest industry-led plastics recycling scheme, taking hard-to-recycle soft plastic packaging out of waste streams and giving it new life.

The NPRS project will make it easier for people to recycle soft plastics at home and creates a new advanced recycling industry here in Australia that can turn used soft plastics back into new food-grade packaging. This creates a circular plastics loop and cleaner recycling streams for all materials, including paper and cardboard. The NPRS project unites brand owners, manufacturers, recyclers and consumers in one powerful, nationwide scheme to transform our plastics problems into circular solutions.

The Australian Food and Grocery Council is developing the NPRS with funding support from the Australian Federal Government’s National Product Stewardship Investment Fund.

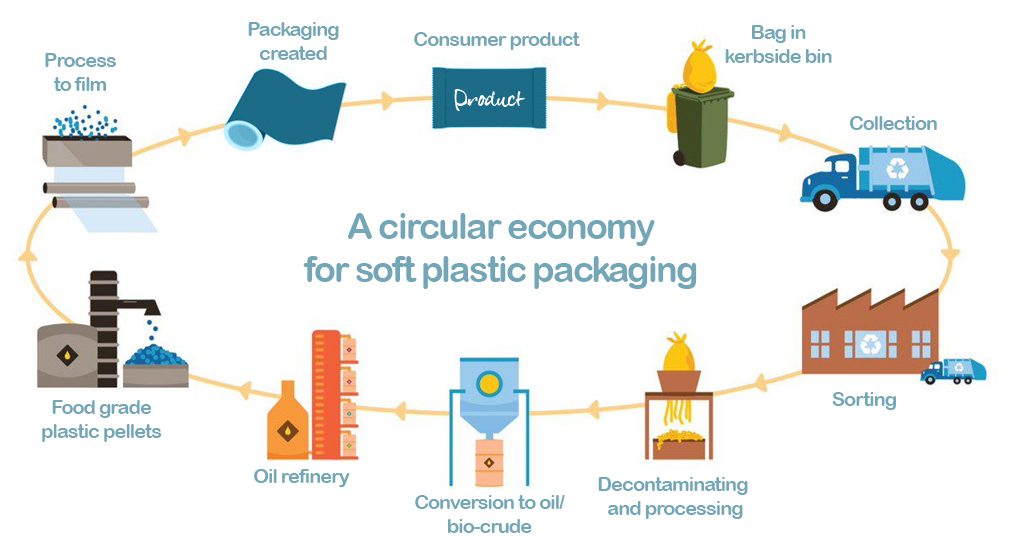

How it works

- The NPRS will collect soft plastic packaging, things like bread and cereal bags, frozen vegetable packets, confectionery wrappers and plastic toilet paper wrap.

- As an industry-backed scheme, food and grocery manufacturers pay a small levy to support the cost of collection and administration.

- Collection will be through an expanded kerbside collection program.

- The bags are extracted from recycling streams at sorting facilities and sent for processing.

- After being sorted, cleaned and shredded, separate soft plastic types are sent to advanced recycling facilities where high-tech processes break the plastic back down into oil – the same type of oil that plastic is made from in the first place.

- That “plasticrude” oil is then ready to be made back into clean, food-grade plastic packaging.

Trials and Pilots

Collecting at scale | The AFGC received federal funding for the NPRS project in 2020 and since that time our work, and FMCG company commitments to purchase recycled content, have changed the landscape for soft plastics recycling in Australia. New confidence has led to announcements by several companies to make capital investments in new, advanced recycling infrastructure and a supply chain that can create food-grade recycled soft plastic packaging.

The NPRS project is now focused on scaled collection and has secured broad support from local councils and the waste and recycling industry for kerbside collection of soft plastics. To find the best model for expanded kerbside collection and processing, limited trials of kerbside collection are being carried out in six Local Government Areas across Victoria, New South Wales and South Australia from November 2022 to March 2023.

Dedicated kits for bag-in-bin trials | Households in trial areas receive specially produced kits containing information on what soft plastics can be recycled and how to recycle them. The kits contain special recycling bags produced and printed for the trial. Participants will be instructed in how to fill the bags, close them and put them in their yellow-lid kerbside recycling bin. Only households in the selected trial areas can take part in the bagged soft plastics recycling trial.

The bins will be collected and taken to a Materials Recovery Facility (MRF) as usual. At the MRF, the recycling bags will be extracted from the waste stream and sent for sorting and processing. The trials will help design the model for kerbside collection and sorting, one that provides a clean stream of used soft plastics and can be scaled up for an emerging advanced recycling industry.

Gathering data | Some councils have decided to run their trials for up to 12 months but the NPRS project will gather data at the three month point to assess the uptake and effectiveness of collection and sorting, as well as quality of material returned. A customer satisfaction survey will also be conducted. All this information will map the landscape of Australian soft plastics recycling for the first time.

AFGC member companies have signed on as Foundation Supporters of the NPRS project, committing funds to the trials and pilots. To view the full list of our valued Foundation Supporters go to our USEFUL LINKS section and scroll down to NPRS PROJECT FOUNDATION SUPPORTERS.

Meeting Australia’s National Packaging Targets

The Challenge

This will be achieved through kerbside collection of soft plastics and expanded bring-back systems to create a clean stream of valuable materials to be recycled and remanufactured as new plastic packaging, ready to head back to the supermarket shelf.

Councils and supply chain

Q: What packaging materials are in scope of the NPRS?

A: Subject to trial results, the scheme plans to collect household post-consumer soft (flexible) plastic packaging from food, grocery, fashion, hardware, healthcare, electrical and general merchandise, and plastic shopping bags used in retail stores or for online shopping. The scheme will not initially focus on post-industrial or post-commercial soft plastics as we understand collection services are developing quickly for those materials.

The focus on soft plastics is aimed at providing the critical feedstock required for infrastructure investment. Creation of that infrastructure will then allow for processing from other sectors and materials, such as bottle lids from glass beneficiation, agricultural plastics and other multi-layered commercial films.

Q: How will the soft plastics be collected and why?

A: The proposed NPRS is open to collection methods that meet the criteria of community convenience – essential for high volumes of material – and high-quality inputs to meet processing quality specifications.

To attain high volumes, the focus will be a “bag-in-bin” kerbside collection model. A cost benefit analysis provided by a waste consultant recommended kerbside collection as the most efficient and effective collection method, due to economies of scale and consumer convenience.

It is proposed that households will use a purpose-designed bag to collect soft plastics. The bag is tied shut and placed in kerbside “yellow lid” recycling bins. Large-scale kerbside collection can be complemented by return-to-store collection initiated by the supermarket retailers comprising the Soft Plastics Taskforce. In areas not serviced by kerbside or return-to-store services, collection via other community waste collection centres will be utilised.

Q: What products are going to be created from the material?

A: After being shredded, decontaminated and sorted, the soft plastic will be sent for further processing according to a waste hierarchy, with priority given to the creation of high-quality, food-grade plastic packaging through advanced recycling. Advanced recycling breaks plastic down into oil that can be used to make food-grade soft plastic packaging, reducing the use of virgin materials. Lower value products in scope include mechanically recycled products such as garbage bags, fence posts, asphalt and concrete additives.

Q: What infrastructure is required to do all this – collection, pre-processing, processing, greenfield developments and site upgrades?

A: The NPRS will contract service providers in areas of the resource recovery supply chain where there is a confirmed market failure. These can include collection, sortation of soft plastics from other recyclables at MRFs, pre-processing to meet quality specifications and advanced mechanical and chemical recycling.

The cost benefit analysis recommends collection using existing council recycling kerbside collection services. There is scope within the NPRS to consider funding to facilitate MRF upgrades, and contracts to design, build and operate pre-processing facilities. Consideration is also being given to funding support for advanced recycling, pending ACCC approval and recommendations from a top-tier consulting firm. The AFGC is aware the federal government has confirmed $60M in the Recycling Modernisation Fund (RMF) to specifically support increasing the circularity of hard-to-recycle plastics, such as soft plastics, as well as funding potentially being available through the National Reconstruction Fund (NRF).

Q: How do the economics work, including how does the proposed scheme work?

A: The NPRS proposes to collect levies from brand owners (including manufacturers and retailers of consumer products) across a broad range of sectors, based on the amount of consumer soft plastic they place on market. Levies will be structured to drive improved packaging design, recyclability and increased use of recycled content through incentives and penalties. Levies collected will be used to assist funding economic gaps in the soft plastic recycling supply chain, including collection, sortation, pre-processing and, potentially, advanced recycling.

The levy structure for supporters of the pilots is currently being determined and will be based on the supporter’s tonnage of soft plastic packaging placed on market (excluding business-to-business soft plastic such as pallet wrap). As the scheme moves into an operational phase, the levy paid will be eco-modulated, providing incentive and penalty adjustments for recyclability and recycled content in soft plastic packaging.

The levy design is a result of extensive research and has been based on the global best practice models of the Fost Plus and Nedvang schemes that operate in Belgium and the Netherlands respectively. These schemes have been successful in driving high recycling rates by maximising the investment in the recycling sector. The scheme designs drive two outcomes:

- As they are based on recyclability and recycled content, the recycling yields and market demand will increase, and

- The funds collected are directly invested in recycling infrastructure with longer-term, national contracts to drive investment confidence.

These schemes differ significantly to the UK plastics tax, that is currently being reviewed due to an apparent failure to drive investment in recycling infrastructure and the inadvertent introduction of a barrier to increased recycled content demand. By eco-modulating these levers within a scheme the results can be assessed annually with periodic adjustments made to the levy incentives and disincentives to drive real outcomes. The NPRS design is being assessed by a top tier consulting firm with circular economy, economics and capital investment expertise who will liaise with relevant parties in the coming months. The results will be shared with relevant parties in due course.

Q: When will this be launched?

A: Initial trials began in late 2022 and the pilot phase, covering additional households and expanded assessments on MRF impacts, is due to begin in late 2023 and continue into 2024. Pending positive outcomes from the pilots, the rollout of an operational scheme is envisaged to start from 2025. It is important to note that kerbside recycling collections will only be expanded in line with contracted processing capacity.

Q: How will the NPRS ensure the majority of plastics is covered and that there is and will continue to be high take-up from AFGC members?

A: To ensure the majority of plastics is covered, the AFGC is recruiting AFGC members, retailers and users of soft plastics from other sectors such as food, grocery, fashion, hardware, healthcare, electrical and general merchandise, and plastic shopping bags used in retail stores or for online shopping.

To be effective and equitable and to provide the required funding levels for infrastructure development, the NPRS needs a broad base of participants. In collaboration with the packaging co-regulator, APCO, industry participation will be monitored to determine the proportion of liable parties that have joined the scheme and identify problematic free riders. The federal environment minister has made it clear in numerous public statements that regulation will be considered should the scheme not be successful.

Q: Will the NPRS leave councils bearing scheme costs and risks?

A: The NPRS is being created to address market failures and economic gaps in Australia’s soft plastic supply chain. It follows the established FOGO model where landfill savings are invested in the system – such as in sortation and processing infrastructure. NPRS levies paid by brand owners support those parts of the system where there are identified funding gaps to avoid additional cost on councils or ratepayers.

Collection of soft plastics will only be scaled up in line with the addition of contracted processing capacity in the NPRS scheme. This is a control to avoid stockpiling situations and mitigate risks to councils and processors. Collections may be via kerbside bins or drop-off at designated facilities. All councils involved in the NPRS trials collaborated in designing collections, messages, bags, audits and distributions. In the trials, all councils opted for kerbside collection. While scheme design is yet to be finalised, collected bagged material ownership is likely to remain with the NPRS to reduce the risk for MRFs and councils and to ensure collected material is recycled.

Q: Does the NPRS impose obligations on producers to utilise recycled content collected or adhere to the CEFLEX design standard?

A: To incentivise recyclable packaging design, and maximise the recycling yield and demand for PCR, the NPRS proposes to introduce higher levies for packaging:

- not meeting CEFLEX design standards, and

- not containing targeted levels of PCR

Q: Will soft plastic collections through MRFs contaminates other material streams?

A: The NPRS understands this concern, and this is a primary driver of undertaking extensive and costly trials and pilots. To assess and validate the impacts on MRF operations and outbound material quality an independent auditor has been engaged to provide qualitative and quantitative assessments of inbound and outbound material quality, of trial material versus control samples.

Additional independent reports assessing community feedback and the polymer composition of collected materials will be shared in due course.

Q: Is there a lack of end market demand for recycled content?

A: Due to the current global shortage of food grade post-consumer recycled content (PCR) for soft plastic packaging, brands cannot procure packaging containing PCR to meet stringent food safety regulations. It is commonly misunderstood that mechanically recycled resin can be used in packaging grade soft plastic film manufacture, however this is incorrect as mechanically recycled resins do not meet the specifications required for soft plastic manufacturing.

Due to these factors, a recent report commissioned by Qenos determined a 99% unmet demand for post-consumer soft plastic resin globally. That means current supply only meets 1% of global demand. This global demand has driven the current infrastructure development plans (see below).

Q: Is there a lack of end market processing capacity?

A: The NPRS has been designed by prioritising creation of end market capacity that meets global food grade standards and will only expand collections once end markets processors are contracted.

Currently, recycling infrastructure can only meet 1% of global demand for post-consumer recycled content that meets food-grade soft plastic manufacturing standards and specifications (see above). Due to this market opportunity, there are currently several published recycling infrastructure developments in various stages of planning and commercialisation in Australia. These include:

- APR Plastics: Currently operating a research and development site with additional capacity scheduled for the second half of 2023.

- Qenos and Cleanaway: Currently planning investments in facilities capable of recycling 100,000 tonnes per annum.

- Licella: Through its subsidiary, Advanced Recycling Victoria, Licella has received government funding and planning approvals for stage 1 of the facilities capable of recycling up to 120,000 tonnes per annum.

- Brightmark: Currently seeking planning approval to construct a 200,000-tonne facility in central NSW.

- Viva Energy: Announced plans to accept 25,000,000 litres of bio-crude from quarter 1, 2024 at their Geelong facility for recycling back into food grade plastics.

Residents taking part in council-run trials of bag-in-bin” soft plastics kerbside recycling

The AFGC and a number of local councils in Victoria, South Australia and New South Wales are conducting trials of kerbside soft plastic packaging collection in specially selected, designated areas. Residents in designated areas will receive information about the trials from their local council and are urged to participate. Here are some answers to common questions about the trials.

Q: I am in the trial area and I have received a kit. What do I do now?

A: Your household has been provided with a pack which contains special bags to collect soft plastic packaging. When a bag is full like a pillow, place it in your recycling bin for the regular council kerbside collection.

Q: I have received a pack, do I have to participate?

A: Taking part in this trial is not compulsory but we’d love you to participate. Full participation in the trial will help build the right model for successful bagged soft plastics recycling in Australia. And you might be surprised at how much more space you have in your regular rubbish bin come collection night.

Q: Is this trial free?

A: Yes, the trials are free. Thanks to the support of the Australian Food and Grocery Council, the Australian government, the food and grocery manufacturing industry and participating local councils, this trial service is provided at no cost to participating households.

Q: What do we mean by “soft plastic packaging”?

A: Soft plastic packaging includes the “scrunchable” plastic bags and wrappers that food, grocery and other products come in. This includes bread bags, breakfast cereal bags, frozen vegetable bags, ice cream wrappers, confectionery bags, cling wrap, bubble wrap and plastic wrapping from toilet paper.

Q: How does the pause of the REDcycle soft plastics recycling scheme affect the trial?

A: This trial is not connected to the REDcycle store drop-off scheme and is not affected by the recent announcement that REDcycle has temporarily paused its scheme. The council trial will continue uninterrupted and the plastics collected in the trial will go for processing at an advanced recycling centre in Victoria.

Q: How do I check what to put in my special recycling bag during the trial?

A: Soft plastic packaging displaying the REDcycle logo and/or the Australian Recycling Label (ARL) “Return To Store” or “In-store Drop-off” logo (Australasian Recycling Label – Planet Ark Recycling Near You) can be included. Even though the REDcycle scheme is paused, you can use REDcycle’s list of what soft plastics can be recycled (What To Redcycle – Redcycle ) as a guide. Residents in trial areas in participating councils can also contact their local councils.

Q: I’ve always been told not to put soft plastics in the recycling bin, and not to put bags full of recyclable items in the recycling bin. Why is this changing now?

A: It’s still the case that loose soft plastics, or any bag holding recyclable items recyclable items, must not go in your recycling bin. Loose soft plastics jam up recycling machinery in trucks and at sorting facilities. The specially made trial bags have been provided specifically to be the right strength and easy to identify and sort when filled and sealed correctly. It’s very important to keep all other items in your recycling bin loose.

Q: Why is this trial happening?

A: Soft plastic packaging does an important job keeping food fresh and safe and keeping products intact and it can be recycled instead of going to landfill. The bagged soft plastics kerbside recycling trial is part of work to design an industry-led scheme for recycling soft plastic packaging in Australia. The scheme aims to create an advanced recycling industry producing recycled, food-grade soft plastic packaging, which currently isn’t made in Australia. The trial is one of a number being conducted to help design the model for kerbside collection and sorting of used soft plastics.

Q: I didn’t get a trial kit. Can our household take part in the trial?

A: Sorry, but only households in the selected trial areas can take part in the bagged soft plastics recycling trial. Please don’t put any soft plastics in your recycling bin if you aren’t part of the trial. With the pause of the REDcycle store drop-off program from 9 November 2022, REDcycle has advised that soft plastics should be placed in your household rubbish bin. Read Redcycle’s statement >>

AFGC member companies (member login required)

For AFGC member companies seeking industry-specific information on the NPRS trials and NPRS scheme design, please go to the FAQs in the AFGC Member Centre (member login required).

SUPPORT

On this page you can find details about the Foundation Supporters making the NPRS trials possible, plus our recycling partners.

NPRS Project Foundation Supporters

As an industry-led product stewardship model, funding support from AFGC member companies has been vital to making trials of kerbside collection happen.

The NPRS Project Foundation Supporters are:

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NPRS processing partners

NEWS

On this page you can find links to information about the councils participating in NPRS project trials, along with associated news and media.

Councils participating in NPRS soft plastic packaging kerbside collection trials:

- Macedon Ranges Shire Council

- Albury and Wodonga councils

- City of Adelaide

- City of Charles Sturt

- City of Port Adelaide Enfield

- Central Adelaide Waste and Recycling Authority (CAWRA) (A joint initiative of the Cities of Charles Sturt and Port Adelaide Enfield)

x - Advanced recycler APR Plastics is receiving soft plastics collected during the trials

Learn more about plastic waste and soft plastics recycling

- Nestlé KitKat wrapped with 30% recycled plastic

- The CSIRO Tackling Plastic Waste mission

- Development licence approved for Licella’s Advanced Recycling Victoria plastic resource recovery plant

- Amcor & Licella partner on new soft plastics advanced recycling facility

Reports

UNPACKED | NPRS Newsletter Archive

- October 2022 (Issue #1)

- December 2022 (Issue #2)

- February 2023 (Issue #3)

- March 2023 (Issue #4)

- April 2023 (Issue #5)

- May 2023 (Issue #6)

- June 2023 (Issue #7)

- July 2023 (Issue #8)

- September 2023 (Issue #9)

Subscribe to the NPRS Newsletter >>

MEDIA RELEASES

Following are links to associated AFGC media release.

- Kerbside trials win new recruits to soft plastics recycling

- Cleanaway and Qenos engage with the NPRS

- Food and grocery manufacturers driving progress on solutions for plastic packaging recycling

- Soft plastics taskforce supports industry-led recycling scheme as the way ahead for Australia

- Kerbside recycling trial aims to close the loop on soft plastic packaging

- Food and grocery industry supports closing the loop on soft plastic packaging with new recycling trials

- Statement on RedCycle

- AFGC applauds joint action on soft plastics recycling

RESOURCES

Communications pack (member-only login required)

The AFGC has compiled an associated communications pack for members containing relevant templates and other collateral to disseminate to their audiences about joining the NPRS. Messages have been provided to ensure consistency and accuracy is shared about the scheme. Communications can be directly lifted or adapted into brand style. Click on the image below to access…

|

General resources

The following general resources may also be used to promote the NPRS across your networks and acknowledge your involvement as a foundation supporter accordingly.

Soft Plastics Summit

Over 200 people participated in briefings in late September 2023 featuring Australian and international speakers on soft plastics stewardship schemes.

Download slides >>

Social media

LinkedIn showcase page >>

Follow us for the latest updates and information on the National Plastics Recycling Scheme project.

LinkedIn tiles

Additional tiles will be added in due course.

|

Image gallery

A selection of downloadable imagery related to the NPRS (more to be added shortly).

|

|

|

|